Remote Isolation Options

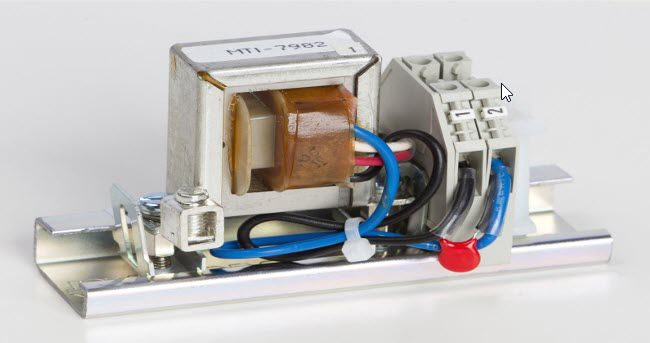

Single Phase TRANSIG

The 9699 model is a rail-mounted current transformer with two terminals for the transformer secondary and ground lugs for the chassis ground. Wiring connections for the transformer secondary outputs are to compression-type terminal blocks. When incorporating the DFR Low Current Analog Input Isolation modules, the Transig units are needed.

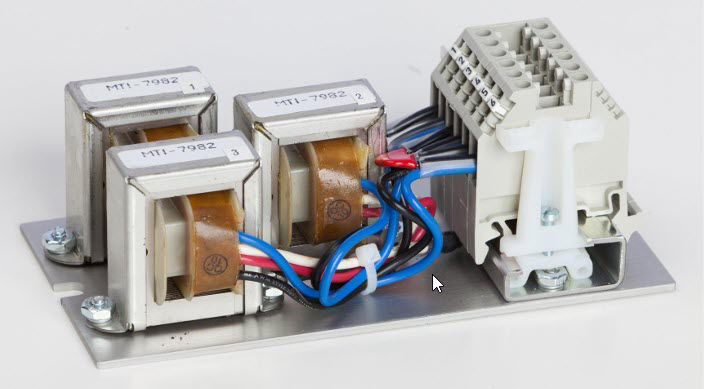

3-Phase TRANSIG

The 9701 model is a plate-mounted 3-phase current transformer with six terminals for the secondary transformer and a ground lug for the chassis ground. Wiring connections for the transformer secondary outputs are to compression-type terminal blocks. When incorporating the DFR Low Current Analog Input Isolation modules, the Transig units are needed.

Split Core CT

The Split-Core Current Transformer interfaces with the analog isolation devices. It is designed for indoor use only and as an auxiliary CT, and breaking the CT circuit is not necessary when deploying the Split-Core CT.

Remote Isolation Module w/ Test Switches

The 9766 model is a self-contained cabinet-mounted isolation module installed into any standard 19" (24" w/adapter) equipment cabinet. The standard configuration is 4RU in height, and all wiring connections are barrier-type terminal blocks.